An aviation company has contracted us to perform aerospace fabrication for their aircraft maintenance team.

To support them, we work closely with their mechanical engineers to develop their designs and specifications into solutions.

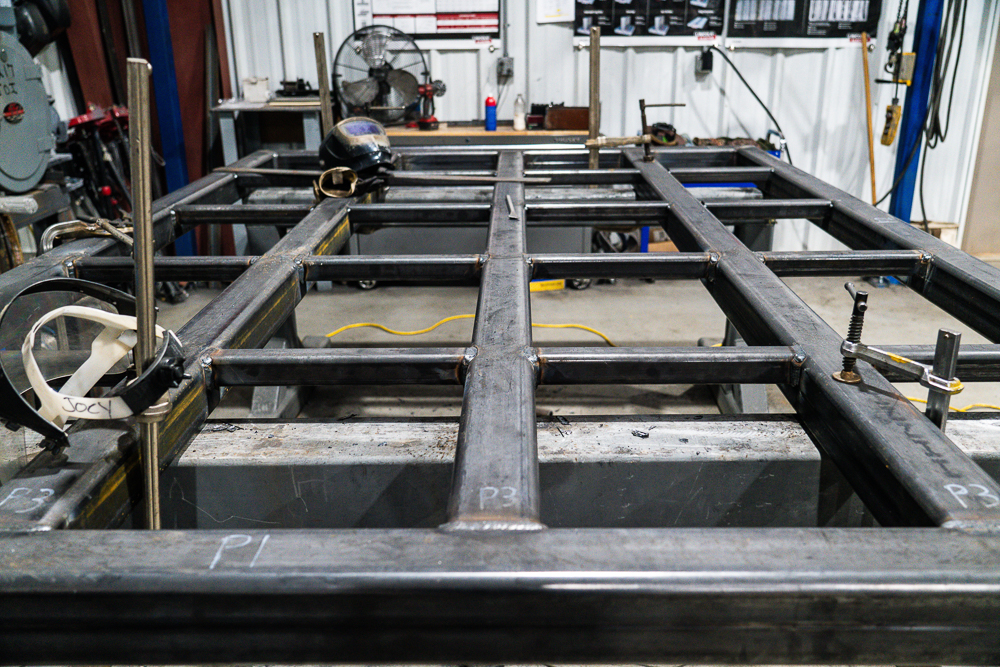

The intention of this fabrication is to support their maintenance team’s access to aircraft components. Prior to final assembly, their team has to have custom steel platforms that support their work before the wings can be attached.