This NOx Scrubber Project is an Industrial Equipment Installation in Upstate, SC for our specialty chemical manufacturing client.

To support them, we employ up to 40 personnel on-site to create a support network for their capital investments.

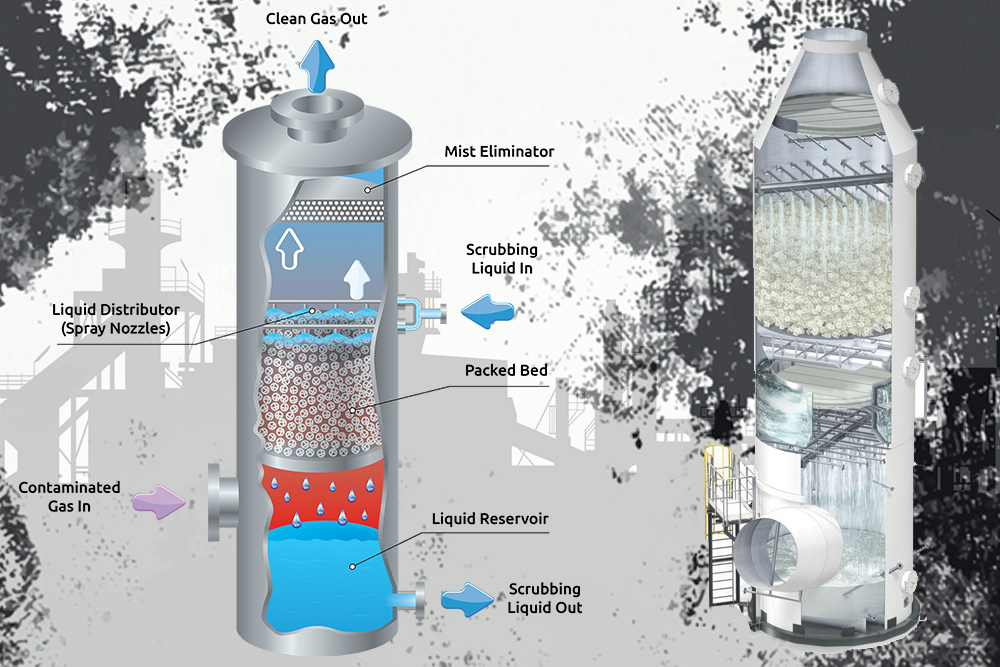

The intention of this installation is to support their refinement process to better the plant’s efficiency and production, with regards to environmental impact.