Full-Service Electrical Installation (240 AMP to 400 AMP)

Robotic Welding Installation Service

Robotic Welding Assembly Project

JDI has completed an electrical service and mechanical project for a client’s plastic injection molding facility in Hart County, Georgia.

The client is automating the welding assembly line for their totes that they create. Their facility contains multiple rows of robotic welders that finish the final product, and we were tasked with installing, powering, and cooling a new row of the robotic welders.

The customer added two components to their robotic assembly line: one being an automated welder station for the cages, and the other being the an automated extractor that feeds into an elevator.

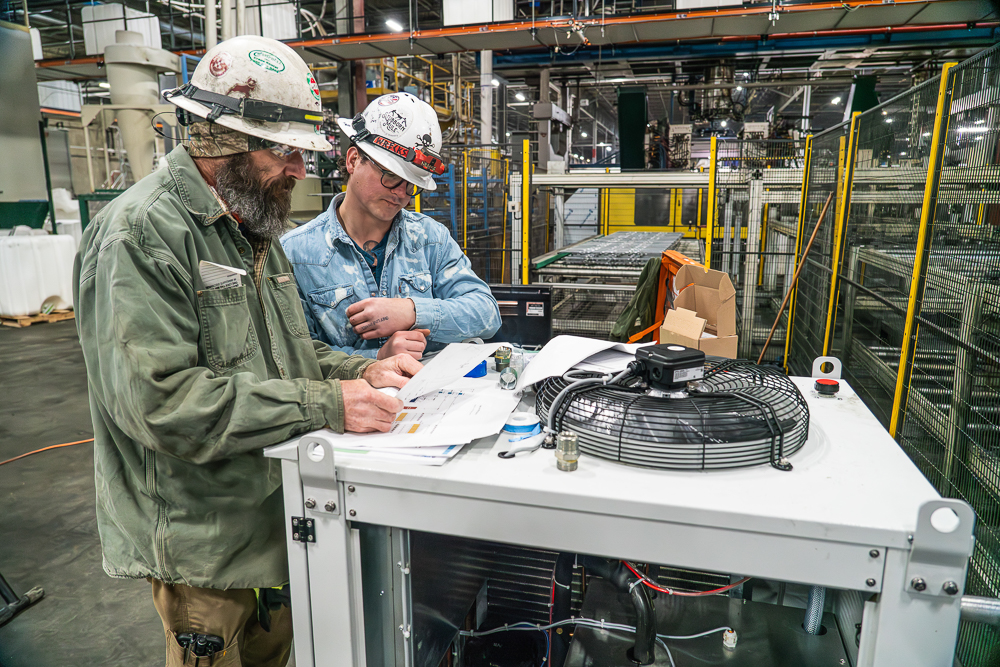

JDI’s part in the project was to convert process, millwright, and perform electrical services. We began by converting the water-coolant based process lines and chiller system to a closed-loop ethylene-glycol chiller system. This mechanical service included welding stainless steel process piping, uncrating the new welder system’s chillers, transporting them into place, anchoring, then connecting the process piping to each chiller.

For the new welder we installed, we had our electrical team perform 250 individual terminations, removed the old conduit and wiring, and replaced with larger gauge wiring and conduit to meet the needs of the new 400 Amp service. Since the chillers were new, we also had to run new control wires for those systems to work properly.

The third component of this was installing the cage extractor. Our millwrights worked with an international vendor to install the cage extractor, including assembly, laser precision alignment, epoxy anchoring, and grouting.

The industrial mechanical team provided startup support for the vendors testing and balancing process, to make sure the adjustments are fine-tuned. We used hydraulic jacks, suspended the extractor to make adjustments, and determined the exact position of placement.

Task Highlights

- 2 Ethylene-glycol Chillers Installed

- Stainless Steel Conveyance Process Piping

- Stainless Welding

- Electrical Service Upgrade and Tie-In

- 400 AMP Panel Install

- 250 Individual Terminations

- Wiring Gauge and Conduit Upgrades

- Full Millwright Service (Assembly, Set, and Anchor) for Robotic Welding Assembly

- Industrial Mechanical Services for Start-Up & Testing

Results

Because of this robotic welding assembly, the customer no longer has human operators physically involved for this part of the stage, providing high-efficiency and more safety for the operators.

The new chiller system has also decreased their production limitations with the installation of a closed-loop ethylene-glycol system. This allows production to run at higher temperatures, for longer, thus providing higher production.

This major update transforms a production system that was not meeting the client’s expectations, into something that does meet their customers’ volume demands as well as their own needs. This success at delivering what they want and need, when they need it, is why they call JDI to regularly perform projects.

Let’s Get Your Project Started

Reach out to our team to get a quote or start the conversation on your next project. We are dedicated to finding the best solution for your industrial needs.