Steel Column Repairs – Part 1

Steel Column Repairs

Steel Column Repairs Overview

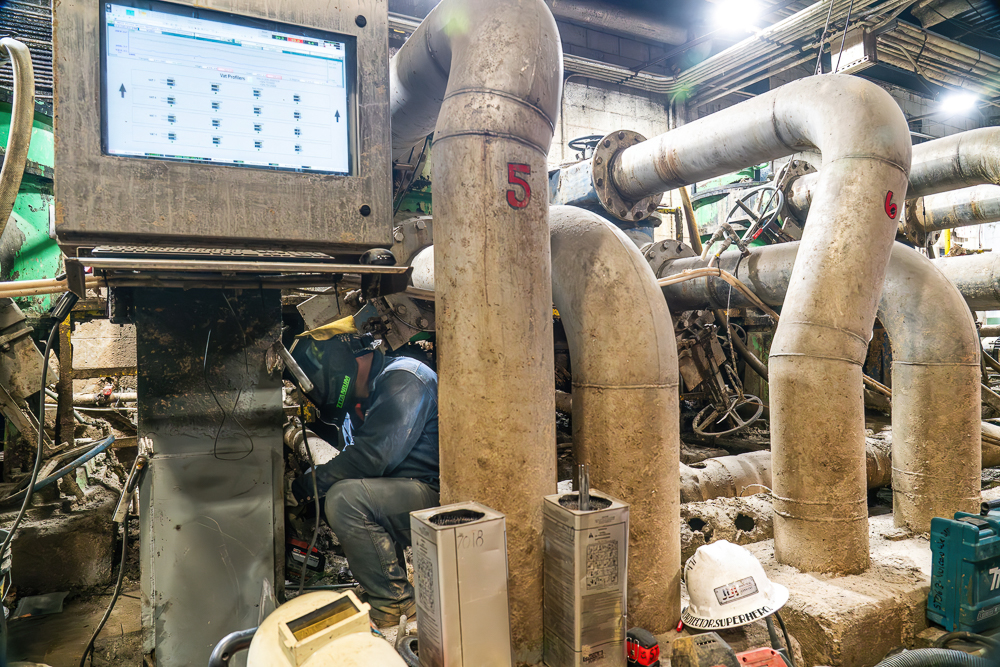

A client in Greenville County, SC contracted JDI Industrial Services to perform a series of steel column repair and replacements. The client had over eight columns that had been badly worn and damaged from water and waste. Our team of expert steel welders came to the site to evaluate, then take care of their needs.

Our welders began the evaluation by looking at the type of steel needed, dimensions, and how much concrete would need to be cut out to access the bases. Our welders perform the steel column repairs and replacements, enhancing the client’s safety, operations, and production by ending their structural worries.

Steel Column Repair Project Details

This older plant over the years has been worn down from a series of wash-down procedures. Our welding team plans with the manufacturing engineers to replace and repair a series of columns due to the washdown causing corrosion of the original steel.

Our project manager began this project by getting the drawings from the client, then creating an estimate that won the competitive bid for the project.

We then began getting field measurements, relaying the information to our fabrication team, and this led to their side of the project.

JDI’s fabrication shop took the drawing and began to create splice plates and replacement column sections. As per the engineers’ specifications we create two different sets of steel components because there are two different size sets of columns.

Before we could begin doing any welding, we clean the columns with wire wheels to find the extent of the corrosion. Our crew then cuts through the concrete to find the extent of the column damage.

The one column line requires us to replace the bottom four feet of column by splicing in a new I-beam with a new base plate. The other column line requires 1-inch thick splice plates. Length and width varies between the steel columns because of the extent of their damage.

All of these columns are on the main level of the plant and enter through to the basement level. We support the weight of the roof with temporary supports.

Steel Column Repairs: On-Site Fabrication & Finish

Initially, the steel column repairs are done with a combination of stick and flux-core MIG welding by our expert welders. All of this steel fabrication work is done while the plant is in full production.

The welding team also works with the mechanical side and redirects the supply lines. This is so that we do not interfere with the client’s process while the steel column repairs take place.

The top face of the I-beam is exposed, and the new baseplate has punch-outs per the drawings in the shape of a capital I. Our welders then began laying the baseplate down on the top of the I-beam protruding from the basement, which requires us to puddle-weld the plates to the existing I-beam.

Thereafter, we insert our new steel section of the I-beam between the existing column and the plating. Our team welds the splice plates on top and joins the steel together.

Finally, JDI’s construction team places concrete back in, then add a high-strength grout around the bases of the columns to prevent the washdown from affecting them from future corrosion. We paint the steel with a Tnemec two-coat epoxy paint system, finishing the project for the client.

Tasks Included

- Grouting

- Concrete Cut-outs

- Steel Fabrication of Plates, Columns, and Bases

- On-site Welding

- Epoxy Application

- Engineering Designs

Results

This client is now able to protect not only their columns from corrosion, but further issues from occurring that could be dangerous to their safety. They are no longer having to worry about the integrity of the structural steel supports thanks to JDI’s welding team.

The area that the steel column repairs supports is vital to the plant’s production and operations, and the client is thankful to have JDI Industrial Services as their contractor.

Let’s Get Your Project Started

Reach out to our team to get a quote or start the conversation on your next project. We are dedicated to finding the best solution for your industrial needs.