For this automotive client, the JDI Electrical team had to reconfigure existing high-voltage 480V electrical bus bars for installation on a new mezzanine structure. The structure featured a conveyor system by Esypro that our industrial electricians knew how to connect.

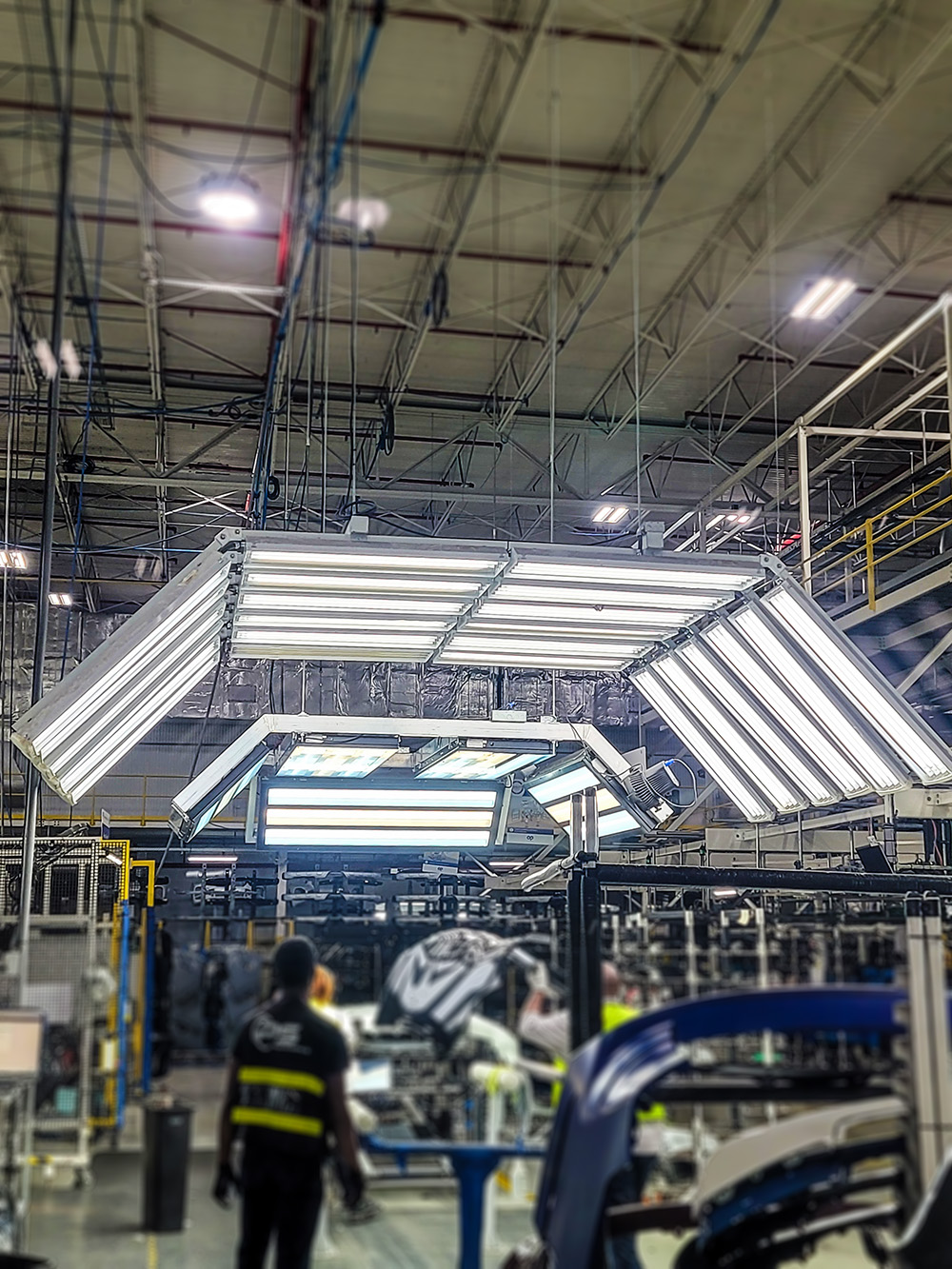

Overall, the team was tasked with rerouting 27 power supplies for existing production equipment; installation of 67 new light circuits and fixtures; ten fans for air movement within the production area, and the installation of three power circuits for new IDF cabinets.

Our qualified electricians are experienced at performing high-tension applications for manufacturers like this one. The team had to work with the structural steel team to create the conduit paths and busbar installations.

Each phase within which the steel team raised their steel columns was then followed by the electrical team’s installation, so that the plant could stay on schedule completing their new car production cell areas.

After this project, we have been continually contracted to serve this client’s electrical needs on a regular basis at their Greenville and Anderson County production facilities. The electrical team has worked on server rooms, MCC installations, and additional production line busbar connections.

Because we can be counted on, this client considers us their number one industrial electrician for high-voltage projects. That’s the JDI difference in delivering expectations with our electrical services.